The Internet simply cannot stop talking about stretch wrap. It’s everywhere: it’s in podcasts, how-to videos, Instagram art pieces, and more. It’s the Taylor Swift of packaging supplies. If it wanted to, stretch wrap could very well break the Internet.

With all the buzz and mass speculation surrounding this enigmatic plastic film, one can reliably expect a litany of questions about what it is and what it does. To keep the Internet from its inevitable breaking, we’ve assembled the ultimate list of the most commonly asked stretch wrap questions, starting with…

What is Stretch Wrap Made Of?

Stretch wrap is typically made from linear low-density polyethylene (LLDPE), a high-strength, moldable plastic material derived from petroleum.

What is Stretch Wrap Used For?

Stretch wrap is primarily used to bundle items together. True to its name, you stretch the plastic film as you wrap it around cartons, pallets, and other loose objects. The strength of the material increases as it stretches and it easily clings to itself, eliminating the need for additional adhesives.

Additionally, stretch film acts as a protective barrier for the load it is bundling. Objects completely encased in stretch wrap are protected from moisture, dust, scrapes, and the handling and jostling that come with packaging and shipping.

We have a video demonstrating how to use stretch wrap for common applications:

What is the Difference Between Cast and Blown Stretch Wrap?

The differences lie in how these wraps are manufactured and the properties they are imbued with.

Cast stretch wrap is formed from a cast extrusion process, where the heated plastic resin is pushed through a super thin slot, producing a sheet of plastic film. Cast is the most common form of stretch wrap, available in wide variety of sizes, gauges, and styles. It is also more cost-effective than blown wrap. However, cast stretch wrap can only provide moderate strength and puncture resistance, depending on the gauge of your stretch film.

Blown stretch wrap is produced by blowing air into the heated plastic resin and continuously spinning the material until it cools and forms sheets of plastic film. Blown stretch wrap is noticeably stronger than cast wraps, providing superior tensile strength and tear resistance. However, blown wraps are less common than cast and are available in fewer sizes and styles. Furthermore, blown wrap is significantly more expensive than cast wrap.

Is Blown Stretch Wrap Better Than Cast Stretch Wrap?

If by better you mean stronger and more durable, then yes. However, as previously mentioned, blown wraps are less common and more expensive. If you’re investing in stretch film soon, you’ll want to make sure the benefits you gain from the type of stretch wrap you use outweigh the costs. Sometimes, cast wraps are the smarter option. It all depends.

What is Tensile Strength?

Tensile strength is the amount of stress that a given material can endure before breaking. Outside of gauge and clarity, tensile strength is the main consideration for judging the quality of stretch wrap.

For reference, a roll of 80 gauge hand stretch wrap has a machine direction (lengthwise) tensile strength of 6500 PSI and a transverse (widthwise) tensile strength of 4100 PSI.

What is Stretch Wrap Gauge?

A gauge, at least as it relates to stretch wrap, is equal to one-hundred-thousandths of an inch. As a point of reference, a strand of human hair is roughly 400 gauge, or 0.4% the length of an inch. 100 gauge is equal to 1 mil and roughly equal to 25 microns.

Most stretch wraps are available in the 60-120 gauge range, with 80-90 gauge being the industry average.

Is Thicker Stronger?

In a very general sense, yes. If you take a set of stretch wrap rolls that are identical in every way except gauge, the thicker films will provide greater strength and durability than thinner films. Of course, the thicker material comes with a higher price.

However, many packaging companies also produce high performance stretch film. These wraps are formed from a specialized manufacturing process so that the material provides a higher performance per gauge than stretch wraps of similar gauges. This means that a 43 gauge roll of high performance stretch wrap could be stronger than a regular roll of stretch film at a much higher gauge.

What’s The Difference Between Stretch Wrap and Shrink Wrap?

Stretch wrap and shrink wrap are often confused with one another. However, these two types of plastic wrap have significant differences between them. While stretch wrap is tightly stretched around loads, shrink wrap is loosely draped over loads and employs heat to contract and encase the items it covers.

One cannot serve as a replacement for the other; this means that shrink wrap cannot stretch far without breaking, while stretch wrap may melt or catch fire if subject to extreme heat.

For more information on the differences between stretch wrap and shrink wrap, be sure to check out our article going over their properties and recommended uses.

What is Pre-Stretched Stretch Wrap?

As noted earlier, stretch wrap is stretched across pallets to enhance the film’s strength and secure the load. However, the constant muscle tension involved in applying stretch wrap can put a lot of strain on workers. Therefore, some manufacturers will pre-stretch some of their wrap rolls close to the breaking point before wholesaling them.

Pre-stretched stretch wrap is not only super strong right from the get-go, but it is also far easier to handle than standard stretch wrap. This alleviates worker fatigue and expedites the wrapping process.

What Size and Gauge of Stretch Wrap Do I Need?

Stretch wrap is available in four main sizes: mini, hand, pallet, and machine length. Mini is naturally the smallest, typically in 2” to 6” widths. Mini wraps are great for bundling small loads and household applications, such as keeping cabinet doors closed. Hand wrap is the next size up, produced in the 12” to 18” width range. Hand wraps are light enough to applied by hand and are ideal for small-to-medium-sized loads.

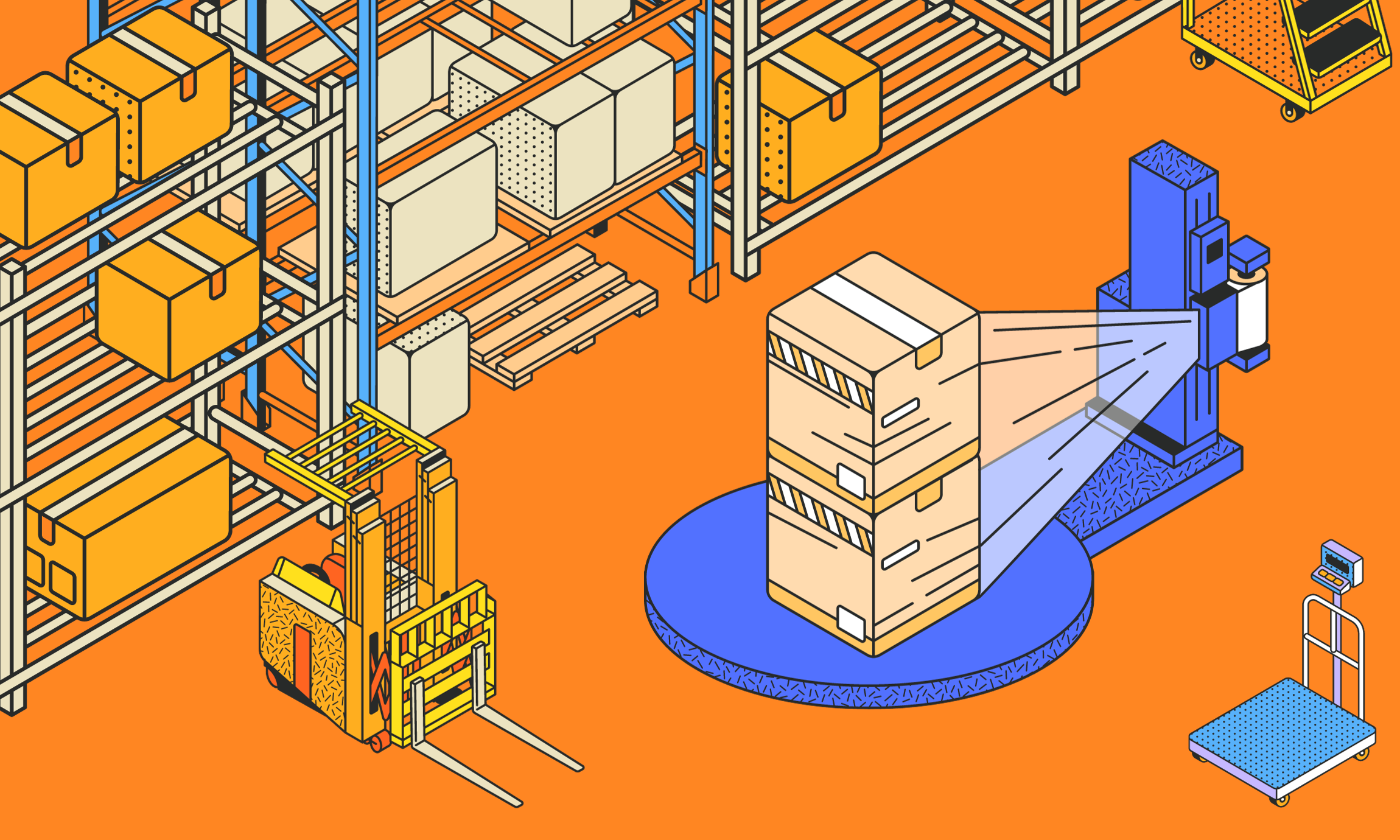

Pallet wraps are next and available in widths up to 20” and 30”. Pallet wraps are defined by their extended cores that can used as handles as workers apply the wrap to medium-sized or large loads. Finally, machine length is the largest size of stretch wrap available, with 20” and 30” widths and up to 10,000 feet in length. Machine length stretch wrap is specifically made to be used with a stretch wrap machine and is best for palletizing a large volume of loads and maximizing throughput in industrial settings.

As for the gauge of stretch film that you’ll need:

63 gauge can support loads up to 2,200 lbs.

80 gauge can support loads up to 2,400 lbs.

100 gauge can support loads up to 3,000 lbs.

These are, of course, general estimations of tensile strength. For specific information on the load-bearing capabilities of stretch wrap, you’ll want to visit individual product pages and see what the specifications state.

Is Stretch Wrap Recyclable?

Being made entirely out of LLDPE, stretch wrap is 100% recyclable. Furthermore, many rolls of stretch film are manufactured from recycled materials.

What are Specialty Stretch Wraps?

As the name would suggest, specialty stretch wraps are stretch films with special properties. Sometimes the stretch wrap offers a unique kind of protection, such as cold resistance or UV resistance. Others feature printed warning messages or breathable material for enhanced ventilation. These wraps are specifically made for materials with unique requirements and special purposes, like corrosion protection or rapid biodegradability.

What is the Difference Between Opaque and Tinted Stretch Wrap?

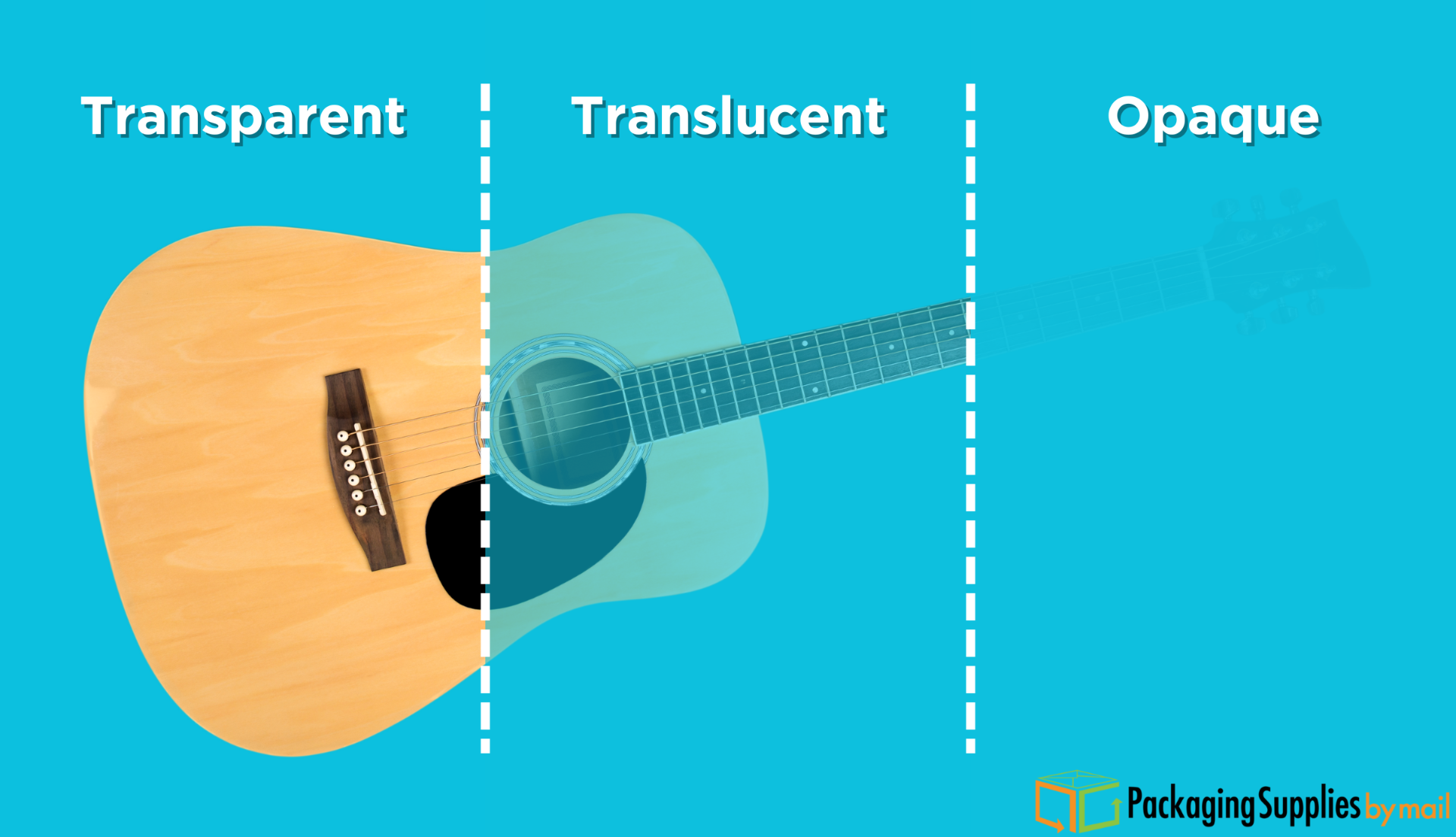

Both of these are boldly colored rolls of stretch wrap. However, the difference lies in transparency.

Tinted wraps are considered translucent, as they allow enough light and clarity so that workers can see the objects encased within the wrap. Tinted film is excellent for quickly identifying objects, organizing your space, and color-coding procedures.

Opaque wraps, on the other wrap, completely obscure the items they’re wrapped around. Opaque film also aids in organizing and color-coding while also concealing your goods from prying eyes and trespassers.

Should I Get a Stretch Wrap Machine?

This is an easy one to answer.

Do you regularly bundle and palletize large volumes of goods for shipping? Then yes. If not, no.

Why Does the Price of Stretch Wrap Fluctuate?

Polyethylene is derived from plastic resin, which is itself a byproduct of petroleum. The price of petroleum is famously volatile and at the mercy of socioeconomic forces and the global supply chain. A financial depression, natural disaster, or act of terrorism can suddenly and without warning spike the cost of petroleum and petroleum byproducts.

How Do I Save Money with Stretch Wrap?

The more stretch wrap you use, the more you’ll have to spend on stretch wrap. Now, this isn’t to say that you should avoid stretch wrap or barely touch the stuff. Instead of using a lot of stretch film, use it smartly. A standard palleted load needs 3 or 4 layers of stretch wrap to be properly secured. If you’re using a high-gauge wrap, you only need 2 or 3 layers to get the same results. Wrap perpendicularly for extra security, alternating between wrapping across and wrapping top-to-bottom.

Moreover, consider the kind of stretch wrap you’re purchasing. Cast wraps will be your lowest-cost option, but will provide the least amount of strength and protection. If you only use stretch film every now and then, it may not hurt to upgrade to blown wraps or high performance wraps. If your business is operating at a large enough scale, you may want to consider investing in a stretch wrap machine.

Any Other Questions?

We’ve answered 16 of the Internet’s hottest stretch wrap questions, but we know we’ve only scratched the surface. Do you have any stretch film questions that went unanswered? Contact us or leave a comment on LinkedIn with your burning, stretchy questions. If we get enough responses, we may put together a sequel to this article.

And while you’re here, be sure you check out our stretch wrap offerings. We have a wide selection of stretch wrap products available in varying sizes, gauges, widths, and properties. And you’ll be happy to know that our stretch film comes with free shipping, so we can do more for you than just answer your questions.