It’s common knowledge that shipping expenses increase when you ship heavy items. But then one day you ship a massive package that only weighs around 10 pounds, yet you’re still hit with substantial shipping costs. Why does it cost so much to ship something so lightweight? It’s because the shipping companies are charging you based on your package’s dimensional weight.

Also known as DIM weight or volumetric weight, this measurement has less to do with the weight of your shipment and more with how much space your shipment takes up. Delivery trucks and shipping containers only have so much space inside and companies are determined to make the most of every cubic inch of it. In this article, we will go over what dimensional weight is, how to calculate it, and a few smart tactics for reducing your DIM weight expenses.

What is Dimensional Weight?

DIM weight is, essentially, the calculation of a package’s hypothetical weight. This hypothetical weight is determined by the shipping company, based on a set DIM factor, or the total allowable volume per unit of weight. The term itself, “DIM weight”, is something of a misnomer; DIM weight is based on the package’s volume and does not factor the weight into the calculation.

When determining shipping expenses, shipping companies will both weigh the package and calculate the DIM weight. If the package weighs more than the DIM weight, companies will charge based on the package’s actual weight. If it weighs less, companies will charge based on the DIM weight.

How Do You Calculate Dimensional Weight?

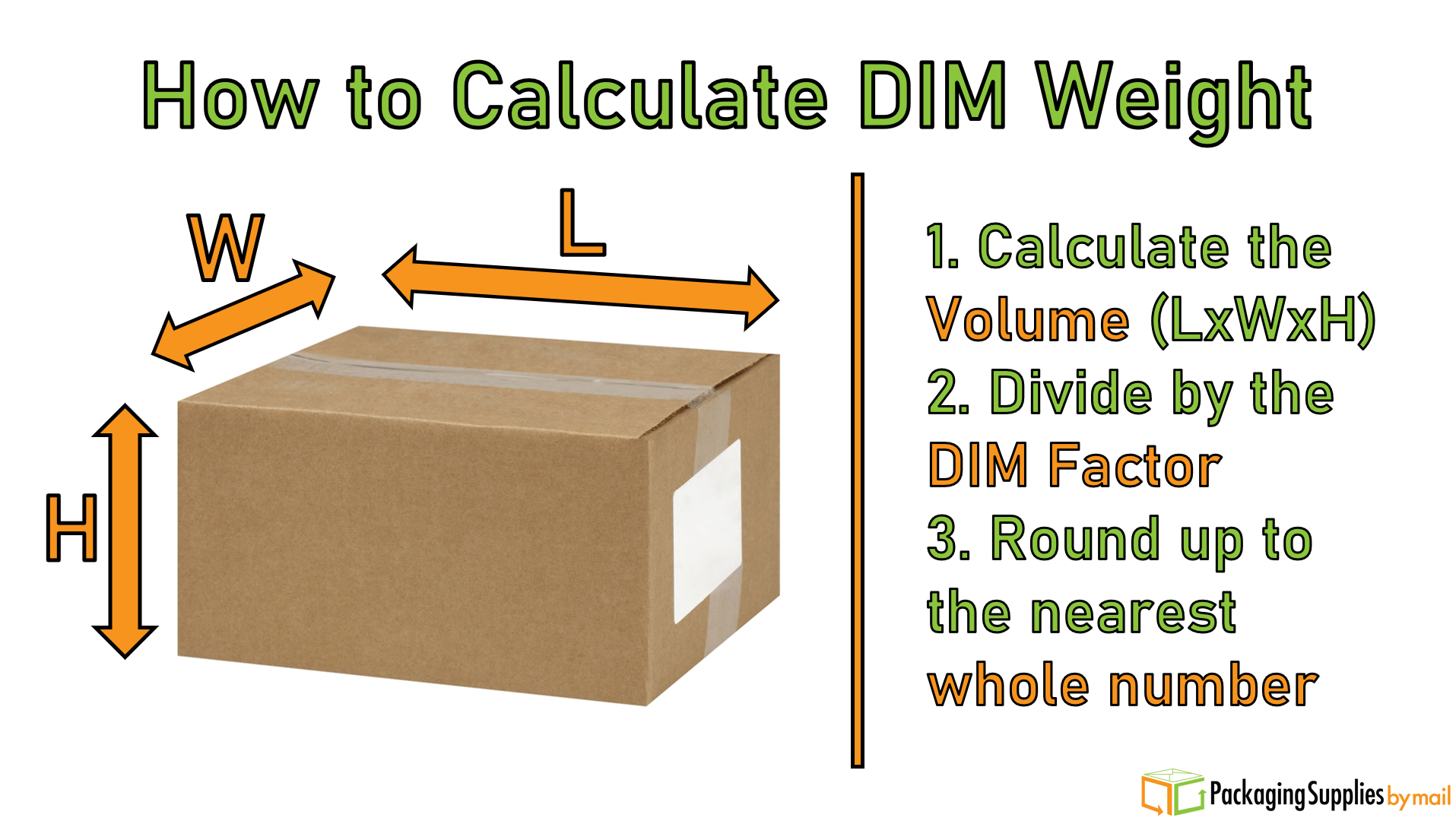

Determining your dimensional weight is actually very simple with these three steps:

1. Calculate your package’s volume (length x width x height).

2. Divide by the DIM factor, which is set by the shipping company.

3. Round up to the next whole number.

UPS and FedEx typically use a DIM factor of 139, while the USPS commonly uses a factor of 166. Therefore, if you have a 20” x 10” x 5” package, your DIM weights are as follows:

UPS/FedEx: (20x10x5)/139 → 1000/139 = 7.194 → 8lbs

USPS: (20x10x5)/166 → 1000/166 = 6.024 → 7lbs

FedEx also has an online calculator for quickly determining DIM weight.

As you can see, the higher the DIM factor, the lower your DIM weight. Be sure you keep your freight carrier’s DIM factor in mind as you prepare for your next delivery.

How Can I Lower My Dimensional Weight?

The short answer is to use smaller packaging. Bulky, oversized packaging will be your main culprit for high DIM weight charges. With that being said, let’s go over some tips to lower your shipping expenses.

1. Right-size Your Packaging

Gigantic, cumbersome packaging is quickly falling out of fashion. Not only are your customers annoyed when they have to open boxes within boxes within boxes just to retrieve their goods, but oversized packaging will spike your DIM weight charges. Try to find packaging that is equivalent in size to the item you’re shipping; boxes and mailing envelopes are available in a wide range of sizes and dimensions. Additionally, some box manufacturers will produce custom box sizes for special customers, so your boxes can be just big enough to hold your goods.

2. Ship Only What You Need

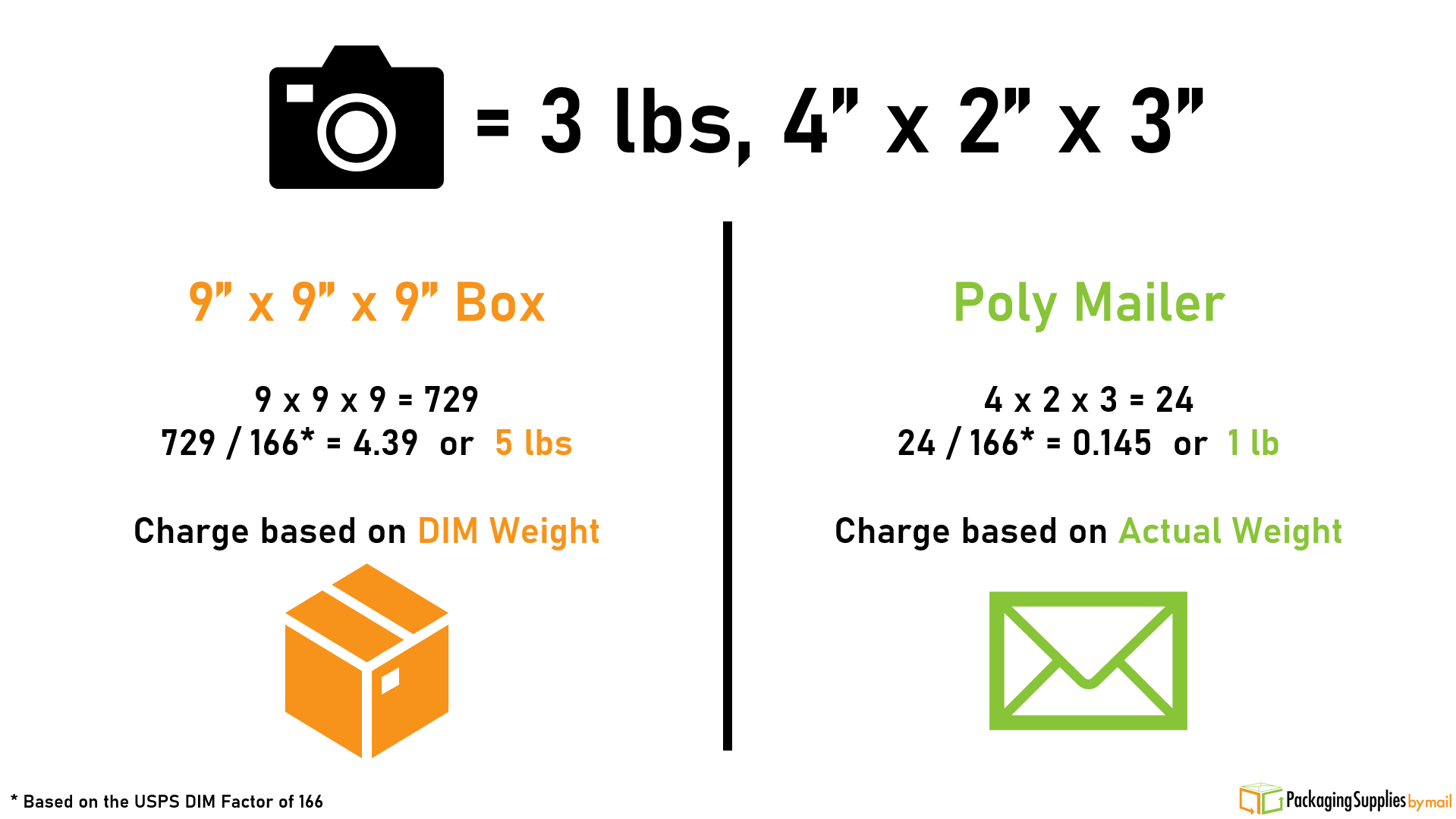

Do you need to ship a pair of socks with three layers of bubble wrap? Probably not. While fragile items like glassware and jewelry should be shipped in boxes with plenty of bubble wrap, non-fragile items like apparel and bedding can be shipped in much simpler packaging. Packaged shirts and pants are durable and can withstand rough handling without damage. Sometimes all you need is a simple poly mailer, which speaking of…

3. Use Poly Mailers

Boxes are big and rigid, making them great at taking up space. Therefore, non-fragile items are best off being packed into a poly mailer. These plastic envelopes are strong and much more lightweight than boxes. Additionally, while boxes can only be the one size, poly mailers can flex, fold, and bend with the shape of the item held inside, making them an excellent space-saving solution.

For more information on the benefits of poly mailers, be sure to check out our article comparing poly mailers to boxes.

4. Negotiate for a Better DIM Factor

This is definitely the most difficult tactic to implement, but it may be worth considering regardless. If you’re dealing with a large volume of shipments, you may want to work with a third party logistics (3PL) or order fulfillment company to contact your freight carrier and negotiate a higher DIM factor. A higher DIM factor means a lower DIM weight, which can go on to save you thousands of dollars in the long run.

And that’s dimensional weight for you: what it is, how to calculate it, and how to reduce it. When your next shipment comes up, don’t just weigh your packages – determine your package’s volume and see whether you’ll be charged for the actual weight or DIM weight. You’ll be surprised how much you can save when you ship with smaller packaging.

Here at PackagingSuppliesByMail, we have a wide selection of packaging materials of various types and sizes. Check out our offerings and see what supplies will be right for you. You may end up with a brighter and better future, simply by shipping smaller.