You’ll only ever have your two hands, so you’d better do everything you can to keep them safe and protected. However, between 2021 and 2022, the second-highest Days Away From Work (DAFW) injury cases for individual body parts were hand injuries at 10.6%, just short of back injuries at 11.2% and narrowly beating leg injuries at 9.0%. Considering the importance of your hands and the prevalence of hand injuries, hand safety is essential.

Hand injuries can happen anywhere and at anytime, from the manufacturing line to even the comfort of your own home. Accidents are always bound to happen, but there are still steps we can take every day to ensure our hands are adequately protected against whatever life throws at them. In this handy article, we will point the finger at three hand safety tips to keep in mind while at work.

1. Use Gloves When Working

This may go without saying, but it bears mentioning nonetheless: the best way to protect your hands against common hazards is a durable and reliable pair of gloves. They’re not just an industry standard—personal protective equipment (PPE) like gloves is often required by law, especially for hazardous work and environments.

Disposable gloves keep your hands safe from dangerous chemicals and substances. These gloves are made from flexible, yet durable materials, such as latex or nitrile. As the name suggests, disposable gloves are made to be used once, then thrown away. The food service industry depends on these gloves to prevent the spread of contaminants and pathogens during packaging, storage, and preparation.

Work gloves protect your hands from sharp edges and points. The gloves themselves are typically made from strong, breathable materials, like cotton or nylon. Sometimes, these gloves are coated in nitrile or polyurethane to make the gloves highly resistant to cuts and punctures. Work gloves are typically found protecting the hands of those working in manufacturing, landscaping, metalworking, carpentry, and more.

2. Prioritize Awareness

No glove will ever offer the kind of protection you get through knowledge and awareness. By keeping yourself and the people around you aware of the potential hazards that come with your work environment, you can minimize the chance of potential hazards becoming actual hazards.

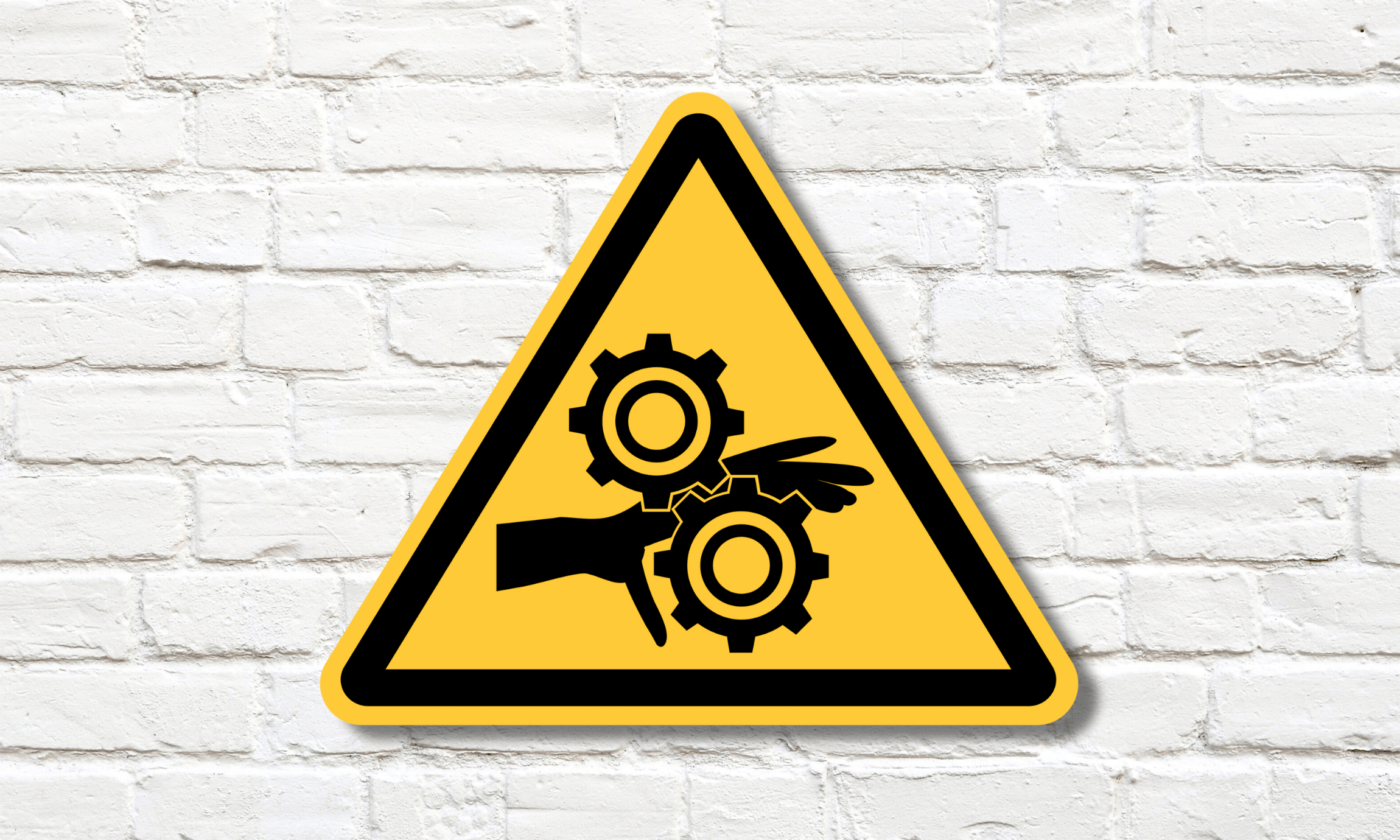

If a worker is about to enter an area or perform a task that may put the safety of their hands at risk, first make sure there is proper signage and communication as to the nature of the environment and/or task. Large letters and universal symbols help in quickly catching the eye. Additionally, place a bin near these signs that’s full of the gloves required to adequately protect their hands. If you can make following safety protocol convenient for your workers, they’ll be more inclined to stay safe.

Furthermore, regularly scheduled safety meetings, at least once or twice a month, will go a long way to keep your workers informed and safe.

3. Minimize Exposure to Hazards

You won’t need to prevent hazards if you can stop workers from being exposed to them in the first place. If you have a workspace that is particularly hazardous, enforce a rule that only authorized personnel can enter and work in that area. Ideally, authorized personnel will be well-informed on how to operate the equipment in this area as well as the environmental hazards.

If you have a machine or piece of equipment that is not in use and does not need to remain powered on the entire time, turn it off. That way, if a worker bumps against the machine and accidentally presses a button, nothing will be activated and that worker’s safety won’t be put in jeopardy.

Finally, acknowledge all Lock-Out/Tag-Out (LOTO) systems. These are put in place so that only the person listed on the tag or lock has access to that particular component. LOTO systems aren’t just essential for workplace safety—they’re legally binding and should be handled with the utmost professionalism and care.

A Helping Hand

Hand safety is no joke. Considering both how much we use our hands on a daily basis and the high likelihood of hand injuries in the workplace, protecting your hands is incredibly important. Gloves are essential pieces of PPE and all your workers should have easy access to them at any time.

However, preventing accidents is a better strategy than resolving them. Make sure your workers are adequately informed of the potential hazards that exist in their specific work environment. Additionally, set a mandate so that only select workers can operate hazardous equipment and any equipment that’s not in use be turned off.

Workplace safety starts and ends with you, so remember these three safety tips to protect yourself and your fellow workers from harm.

For more information on our PPE, be sure to check out this article all about hard hat types and classes.