Packaging can be quite stressful, but perhaps not in the way you’re thinking. While you may be dealing with the stresses of deadlines, customer demands, and daily operations, your packing tape will encounter a different kind of stress: adhesive stress.

Adhesive stress refers to how the adhesive bond is pulled, stretched, and otherwise deformed when acted upon by external forces. In this sticky article, we will go over the five types of stress your tape will face throughout packaging and shipping.

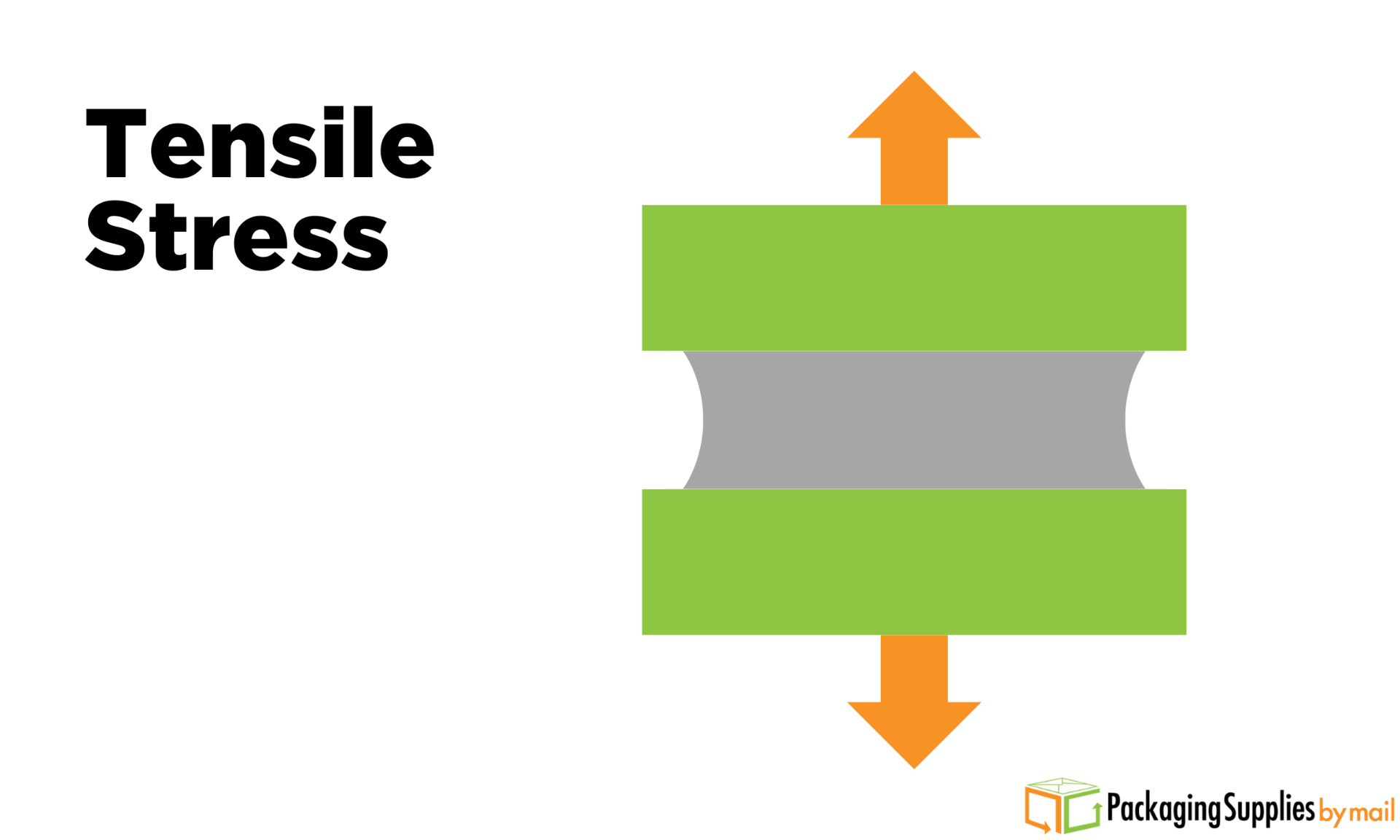

Tensile Stress

Tensile stress occurs when the adhesive bond is elongated or pulled apart by external forces moving away from each other. The direction of the pulling is perpendicular to the bond and the stress is distributed evenly across the surface.

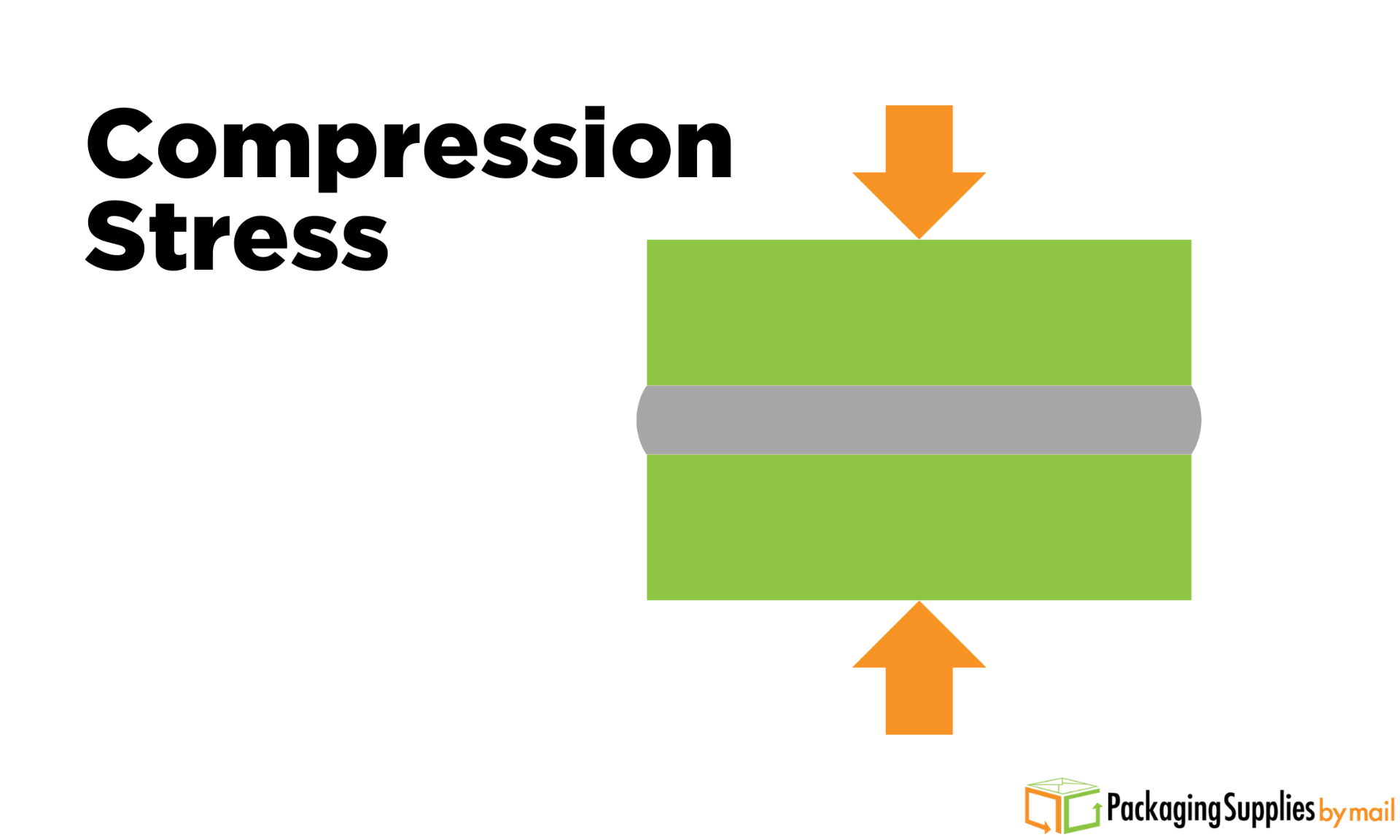

Compression Stress

This is the inverse of tensile stress, where the bond is compressed or smushed by external forces moving toward each other. Like tensile, the direction of the stress is perpendicular to the bond and is distributed evenly.

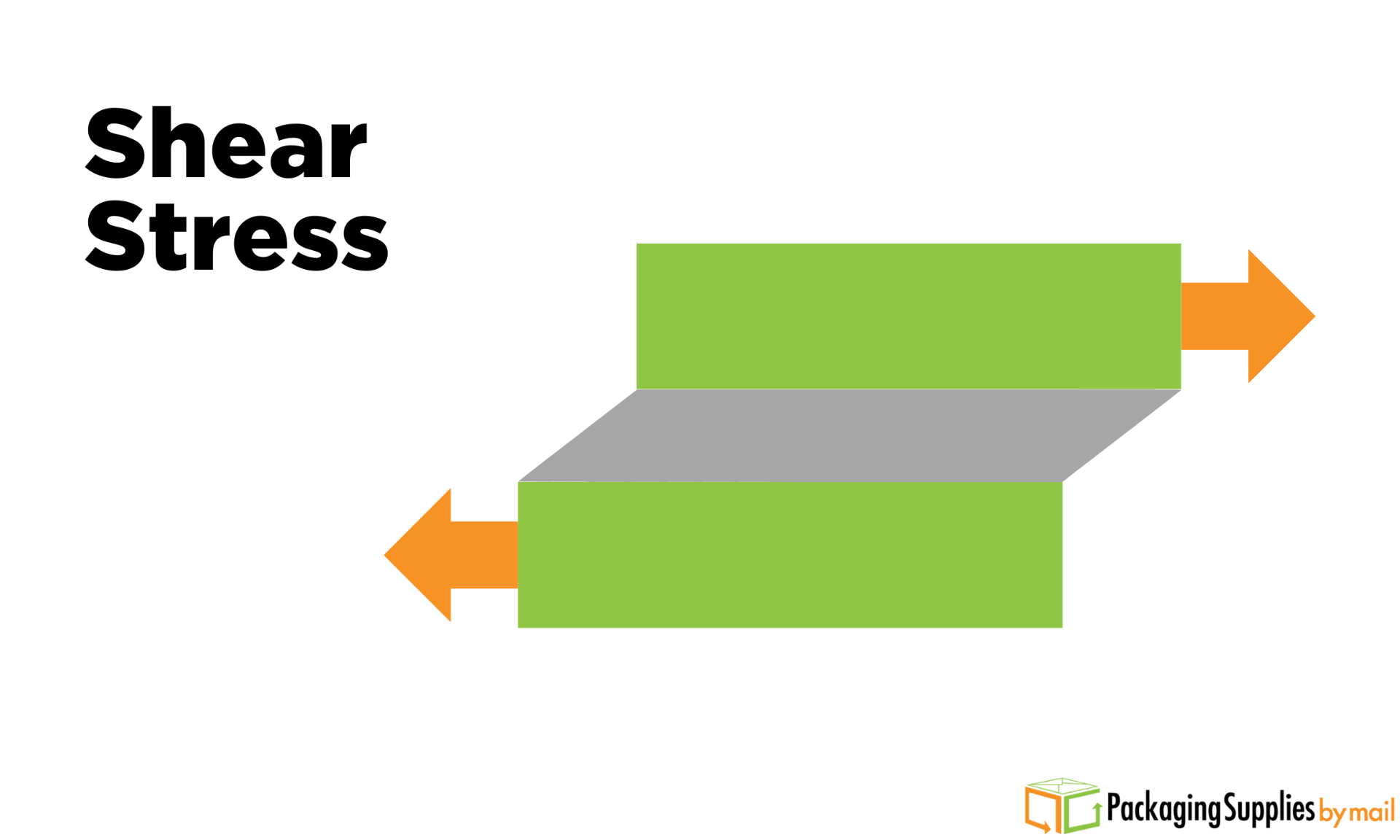

Shear Stress

Unlike the previous two, shear stress involves external forces moving across each other, parallel to the bond surface. This stress stretches the adhesive bond laterally. Despite the change in direction, the stress is still evenly distributed across the bond surface.

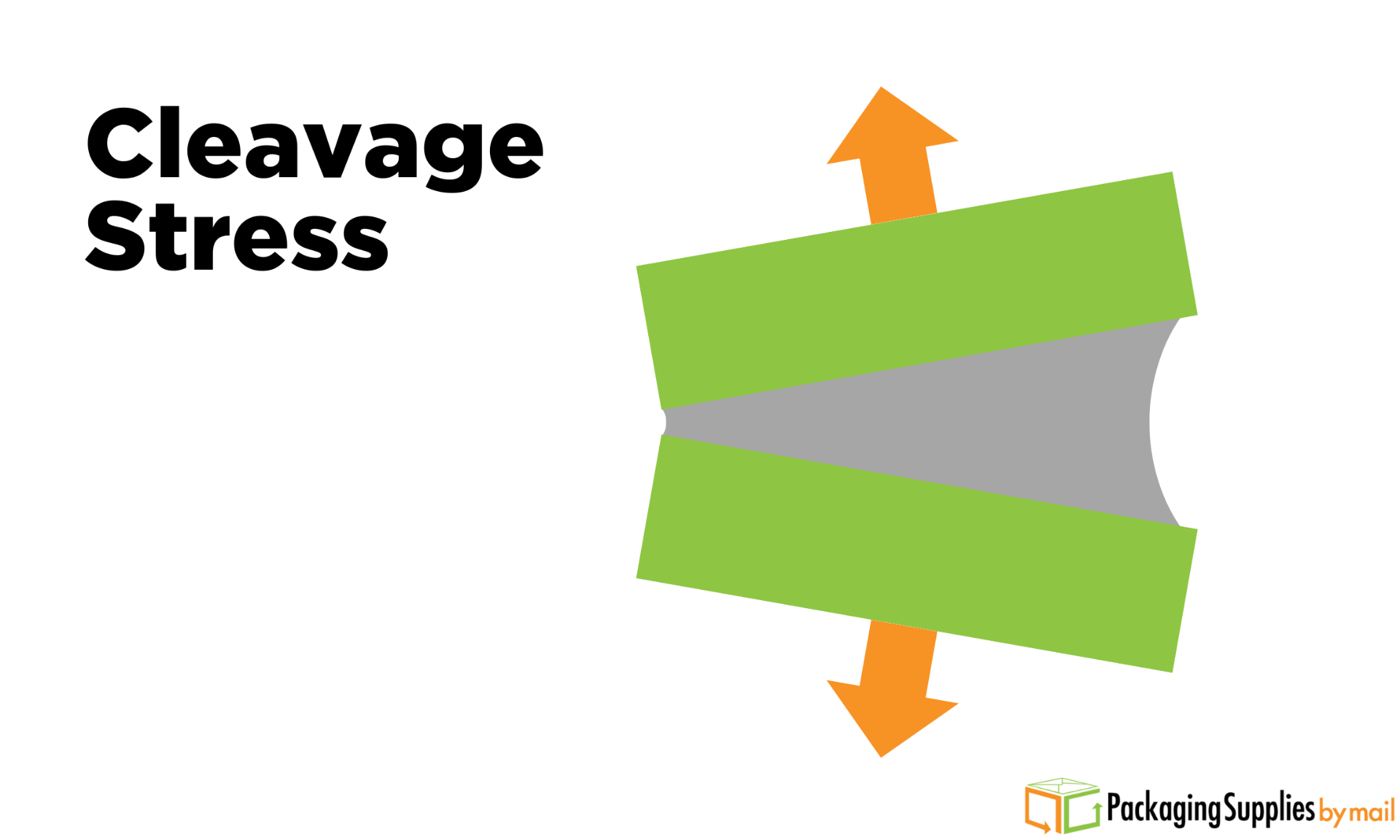

Cleavage Stress

Cleavage stress involves external forces pulling apart one side of the bond while the other side experiences little to no stress. While the previous three stresses are evenly distributed across the entire area of the bond, this stress is uneven and concentrated on a single side.

Peel Stress

Peel stress is similar to cleavage, as the external forces pull apart one side and leave the other side alone, putting uneven stress on the bond. In this instance, however, at least one of the surfaces is flexible, such as a tape backing. This results in greater stress in the area getting pulled apart, making it a more extreme form of cleavage stress.

Stress Management

Adhesive stress is the challenge all tapes must face. Whether it’s sealing boxes, hanging decorations, or making repairs, tapes must be able to stand up to the forces trying to pull them apart.

At the same time, some specialty tapes, like masking and painter’s tape, are specifically formulated to easily give way to peel and shear stresses so they can be removed quickly and cleanly. So the next time you need to use some tape, consider what you’re using it for and what kind of adhesive strength you need.

While you’re here, be sure to check out our selection of tape products, available in a wide variety of tensile and shear strengths. All our tapes come with free shipping, so you can tackle the challenges of adhesive stress today.

For more information on adhesives, take a look at our article comparing pressure-sensitive and water-activated tapes.