You should always make sure your packages are safe and secure during transportation or storage. One of the best ways to ensure this is to use shrink wrap or stretch wrap. Despite often being confused for one another, shrink wrap and stretch wrap have many key differences that make them distinct. This article will explain what these different packaging materials are, what sets them apart from each other, and what they can do for you.

First thing to note: stretch film is not shrink film, and shrink film is not stretch film. This may seem like an obvious fact (it’s the subject of this article), but this point should not be overlooked. Stretch and shrink are two very different things, as this article will elaborate on, so when you place your next order of plastic wrap, make absolutely sure you are ordering the right materials.

What Is Stretch Wrap?

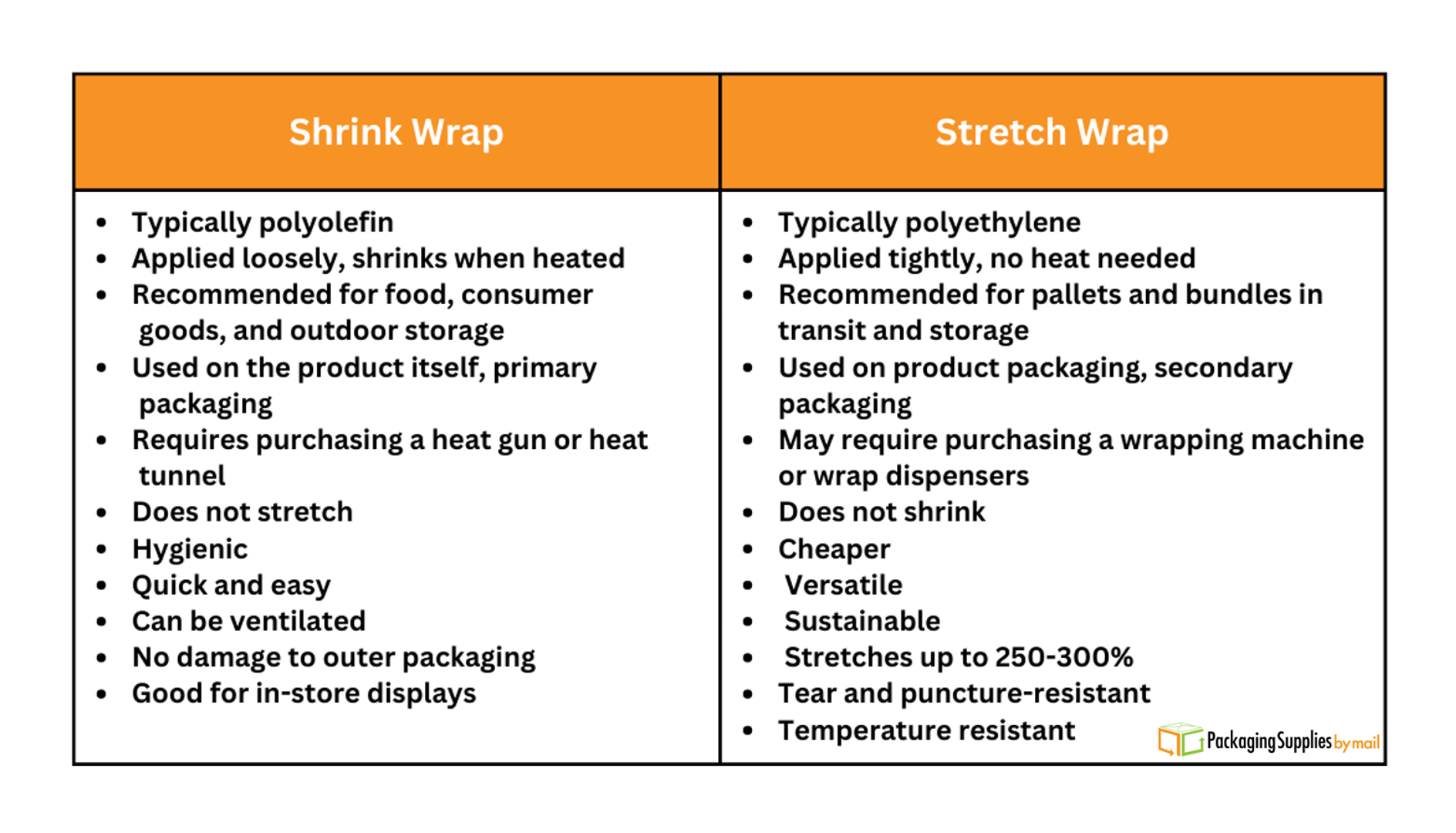

Stretch wrap, or stretch film, is commonly made of polyethylene plastic. Stretch wrap is tightly wrapped around pallets and bundles to hold items together as one solid unit. The film clings to itself and can be applied manually with a wrap dispenser or automatically with a stretch wrapping machine. Stretch film can stretch up to 250-300% from its original form, depending on the type, gauge, and characteristics of the material.

Stretch wrap is secondary packaging, meaning that it is applied to the outer packaging of the product. Stretch film is ideal for warehouses and distribution centers where workers need to secure a large volume of pallets. At the same time, stretch wrap’s versatility means it also works great with moving companies and retailers needing to transport furniture, office supplies, and other small-scale goods. Stretch film comes in many sizes and varieties, including specialty wraps like ultraviolet inhibitor (UVI), volatile corrosion inhibitor (VCI), and anti-static. Furthermore, stretch wrap is considerably more cost-effective than shrink wrap.

Despite this, large-scale wrapping jobs may necessitate acquiring a stretch wrapping machine, a highly specialized and costly piece of equipment. Additionally, stretch wrap cannot be exposed to the same high heat that shrink wrap is without risking damage or fire.

What Is Shrink Wrap?

Shrink wrap, or shrink film, is typically made of polyolefin plastic. Shrink wrap is a loose-fitting material that contracts when heat is applied to it. The heat is provided either by a manual heat gun or through an industrial heat tunnel.

Shrink wrap is primary packaging, which means that the material is usually applied directly onto the product itself. This makes shrink wrap great for frozen food, produce, gadgets, and other consumer goods; by extension, shrink film is great for items that will be displayed on store shelves. Shrink film is hygienic and can be ventilated to prevent condensation from spoiling your goods.

However, using shrink wrap necessitates purchasing heat guns or a heat tunnel, which are specialized, expensive pieces of equipment. On top of this, given that the film is designed to shrink in the presence of heat, constricted shrink wrap can barely stretch without tearing.

To get an idea of how it works, Packaging Digest has a great video and article showing various products being wrapped in shrink film and going through a heat tunnel.

What Wrap Should You Choose?

In short, it all depends on the job at hand. Shrink wrap is great for front-of-house applications, meaning that this is packaging that the customers will see and interact with themselves. As such, shrink film is ideal for securing beverages, movie and video game cases, produce, smartphones, and other consumer goods. Just remember that it needs to be activated with heat in order to properly secure your items.

Stretch wrap, on the other hand, is primarily for back-of-house use, which means this packaging material is usually handled by workers staffed in warehouses, distribution centers, and shipping enterprises. Stretch wrap excels in large-scale applications where it can wrap several pallets and bundles in an hour. While a stretch wrapping machine can maximize your capacity and throughput, stretch film can just as easily be applied by hand.

We here at PackagingSuppliesByMail have a wide assortment of stretch wrap available for purchase, from mini to machine length, clear to opaque, and plenty of specialty stretch film to meet whatever job comes your way. Plus, we offer free shipping. So let us become your number one source for all your packaging needs.