For all its benefits, stretch wrap is not without its drawbacks. Since the plastic film needs to be kept taught as it is wrapped around items and loads, worker’s hands can eventually develop stress and fatigue. Additionally, the paper core and thin plastic can chafe and irritate your hands.

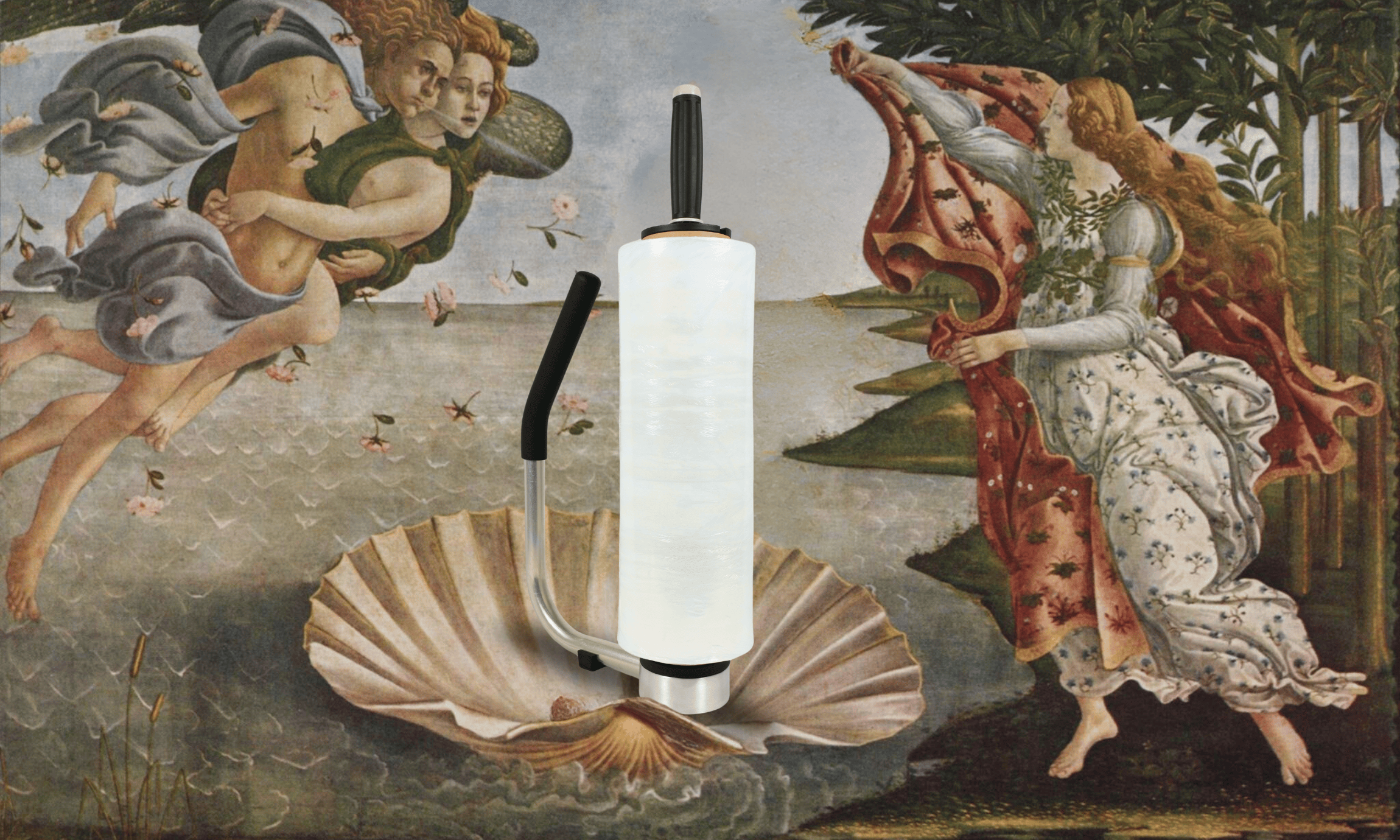

That’s where a stretch wrap dispenser comes in. This handy device offers both an adjustable tensioner and an ergonomic grip that’s much easier on the hands. And thankfully, setting one up is quick and easy. In this article, we will cover how to assemble a stretch wrap dispenser, as well as some basic tips on using it.

We also made a step-by-step video that you can follow along to:

Choose the Right Size

Before you load your stretch wrap, you want to make sure you’ve got the right size for your dispenser. Dispensers are typically made to accommodate a set range of stretch wrap lengths, such as 15” – 20” or 20” – 30”.

Check the recommended size range for your dispenser and purchase your stretch wrap accordingly.

Load the Stretch Wrap

First, unscrew the tensioning screw and release the top end cap, setting it aside.

Next, slot the stretch wrap around the tensioning screw and place the wrap on the bottom end cap.

Secure the Tensioner

Slot the top end cap around the tensioning screw and place it level on top of the stretch wrap.

Continuously screw the tensioning screw into its place until it holds the stretch wrap steady and is set to the desired amount of tension.

Start Wrapping

Secure the end of the stretch wrap under the load or between two items and, gripping the dispenser by the handle, wrap the load from top to bottom in 4-to-5 layers of stretch film.

Adjust the tensioner if needed so that the dispenser applies an adequate amount of tension to the wrap without tearing it.

When you’re finished wrapping, tear or cut the film from the roll and press the self-clinging wrap against itself to keep it together.

The Indispensable Dispenser

And that’s how to assemble a stretch wrap dispenser! It may be a simple device, but it makes a big impact. The ergonomic grip and adjustable tensioner significantly reduce the stress that workers’ hands often endure. It’s lightweight, durable, and super handy to grab and wrap at a moment’s notice.

Furthermore, there are varieties of dispensers with extended handles or magnets to serve a wide range of needs. If you use stretch wrap with any amount of regularity, a stretch wrap dispenser is exactly what you and your workers need.

If you’re wondering whether or not you should upgrade to a stretch wrap machine, check out our article covering 4 signs that you should make the switch.