Tape. It’s everywhere, isn’t it? It seems like you can barely take a step outside your front door without tripping over a stack of duct tapes or masking tapes. We all know what it does—it’s sticky and it holds stuff together—but do you know about the different types of packing tapes and adhesives? If you feel like you’ve got a learn to learn about this subject matter, then let this article serve as your beginner’s guide to the wild and wacky world of tape.

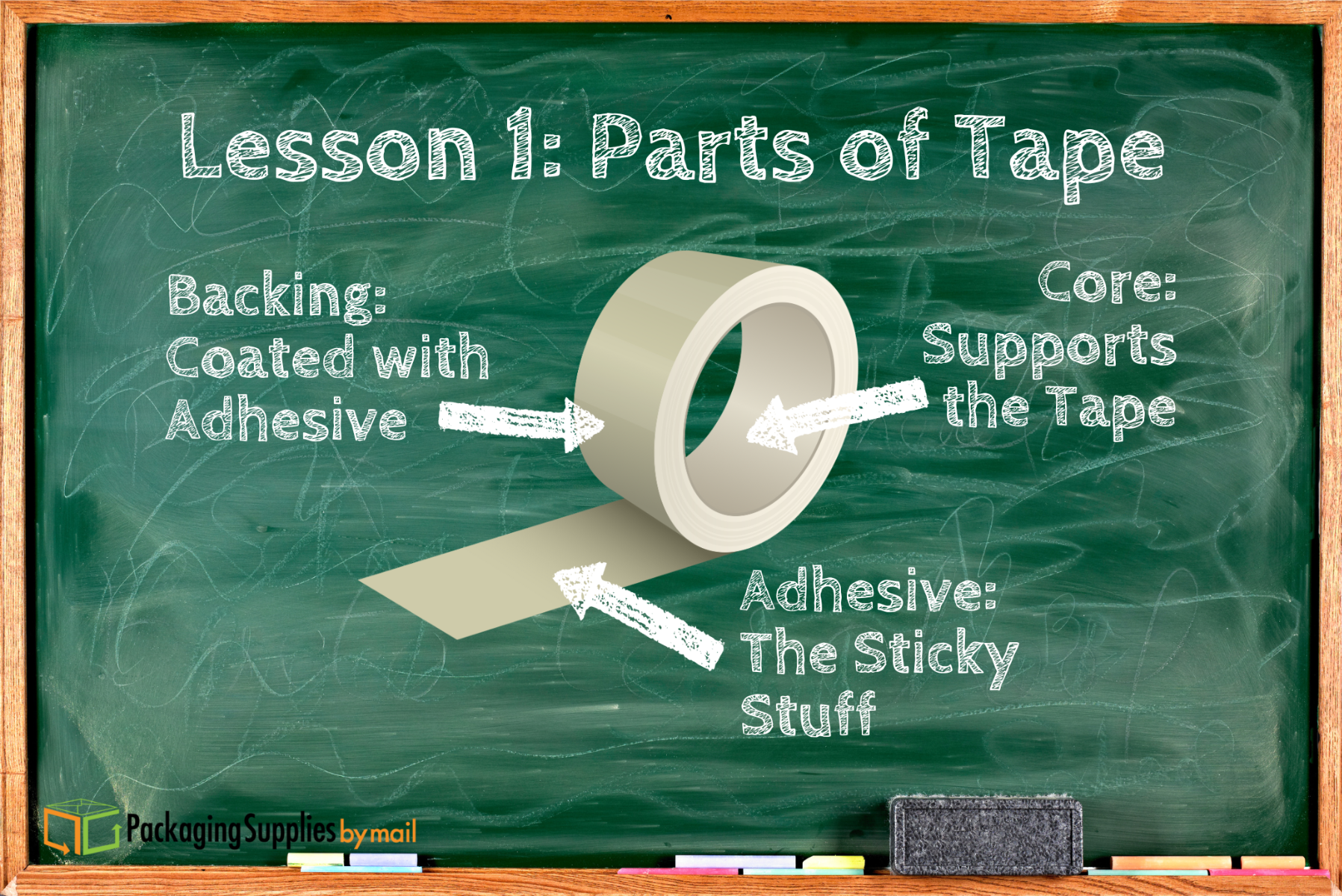

What is Tape?

Tape is a standard packaging material that keeps cartons and boxes sealed, clings items together, and holds items in place, as well as countless other applications. Tape is comprised of two basic parts: the backing and the adhesive.

What is the Backing?

The backing, also known as the carrier, is the material that is coated with the adhesive on either one or both sides. Most tapes are made with plastic backings, such as polyethylene (PE) or polyurethane (PUR). Other kinds of tape are produced with backings made of paper, cloth, foil, and more. For extra support, some backings are manufactured with strands of fiberglass embedded into the material. Your tape’s backing material will affect its tensile strength, or its resistance to tension, as well as its resistance to tearing, moisture, ultraviolet light, temperature, and the elements.

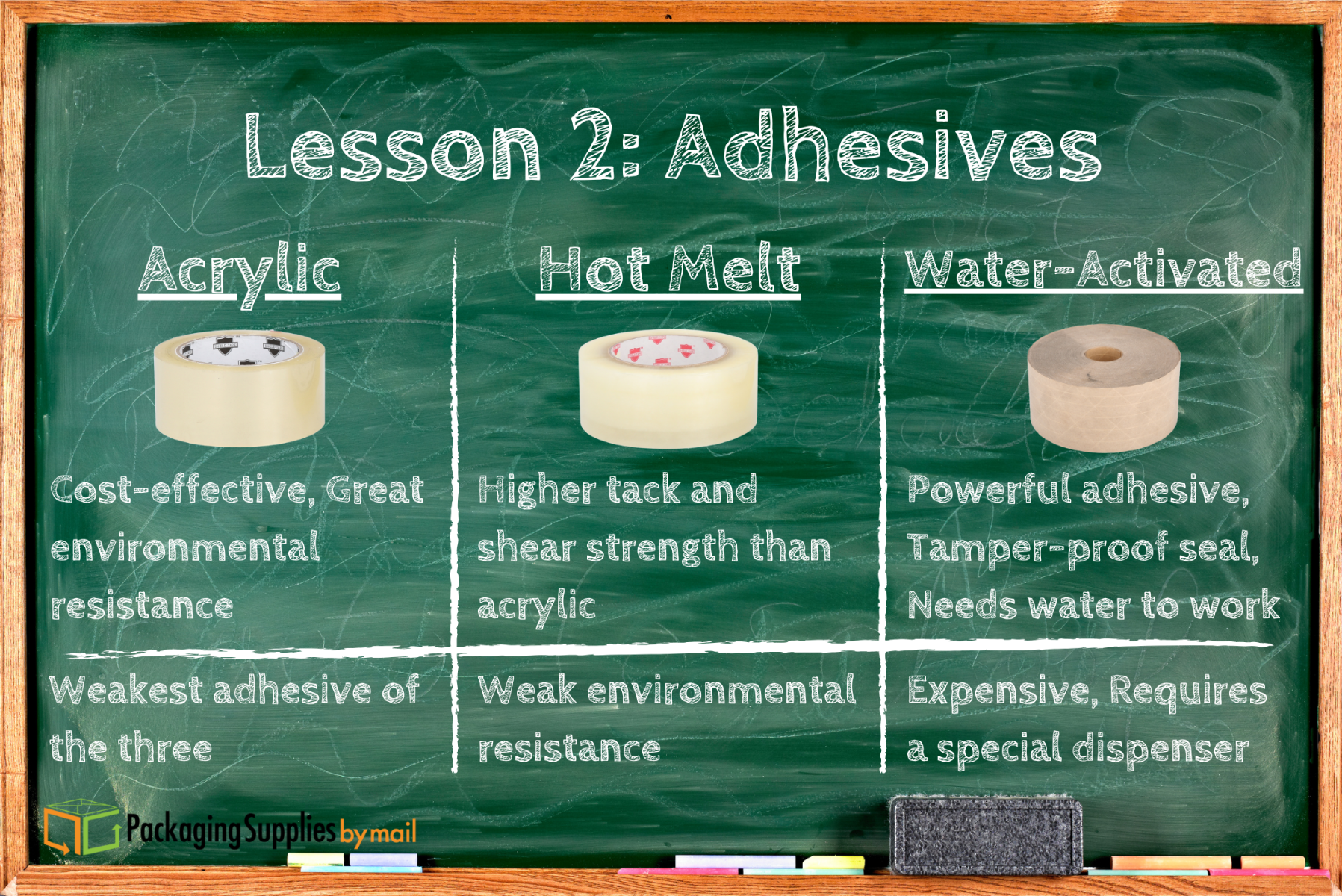

What are the Types of Adhesive?

There are three main types of adhesive used for tape: acrylic, hot melt/rubber, and water-activated.

Acrylic

Acrylic is the most common tape adhesive and is produced for pressure sensitive tapes, or tapes that are fixed into place with a light application of pressure. For one, acrylic is the least expensive adhesive of the three and therefore the most widely available. Acrylic also has great resistance to the elements, as it can stay strong in extreme temperatures, high humidity, and under ultraviolet light. Furthermore, acrylic adhesive strengthens over time, making acrylic-based tapes ideal for long-term storage.

However, acrylic has a relatively weak tack, or the time it takes for an adhesive bond to form. On top of this, acrylic is generally considered the lightest and weakest adhesive of the three. So while acrylic tapes can handle a wide range of needs, you should probably use a different kind of adhesive for your more important and demanding jobs, such as…

Hot Melt/Rubber

Hot melt and rubber adhesives are a step up from acrylic in terms of tack and adhesive strength. These pressure sensitive adhesives are “stickier” than acrylic, so they’re less likely to loosen once stuck in place. Hot melt and rubber also have a higher shear strength, or the ability to resist the motion of surfaces moving in laterally opposing directions. These adhesives are ideal for sealing up heavy-duty and critical items and loads.

Hot melt and rubber are not without their downsides. First, they are more expensive than acrylic and therefore less widely available. These adhesives are also more sensitive to extreme temperatures and high humidity. And when exposed to UV rays, hot melt and rubber tapes will yellow and weaken over time.

Both acrylic and hot melt/rubber adhesives are used with a variety of backings, including plastic, paper, cloth, and foil.

Water-Activated

Water-activated adhesives are arguably the strongest of the three. These adhesives are not immediately sticky and won’t be able to keep things sealed or clung together, even with a light application of pressure. But the secret lies in the name: the adhesive needs to be activated with water. These adhesives are often made with starches or like substances that chemically react with water to become sticky.

Water-activated adhesives are so strong because the adhesive penetrates the fibers of cardboard boxes and cartons, effectively fusing with the material. This effectively creates an additional of tamper-proofing, as the tape cannot be removed without damaging it or the package underneath. Almost all water-activated tapes are made with a kraft paper backing, with many featuring fiberglass stranding for enhanced tensile strength. While water-activated tapes may be the strongest and most secure, they are also rather expensive and require water-activated tape dispensers to function.

For further reading on the differences between these adhesives, we have articles comparing acrylic and hot melt tapes as well as pressure sensitive and water-activated tapes.

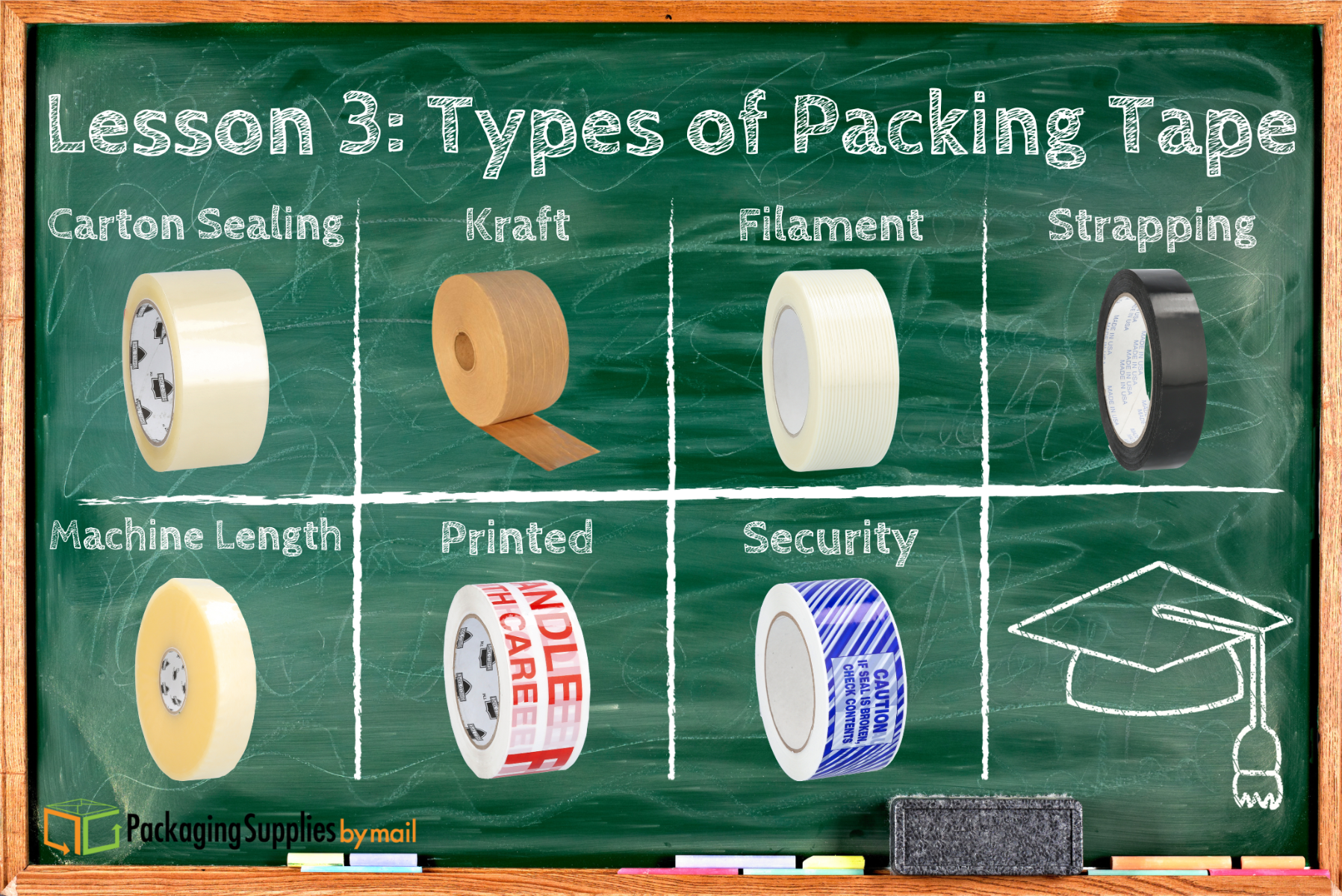

What are the Types of Packing Tape?

Different types of packing tape provide differing levels of adhesive strength and environmental resistance, or they may have special properties that are ideal for specific situations.

Carton Sealing Tape

As the name suggests, this tape is used for sealing cartons, boxes, and other kinds of packaging for shipping, handling, and storage. Carton sealing tapes are typically pressure sensitive and are usually produced with plastic backings. Carton sealing tapes can be made with either acrylic or hot melt/rubber adhesives. These tapes are specifically made to handle the rigors of packaging and shipping, keeping packages sealed and secure from start to finish.

Kraft Tape

Kraft tapes are high-strength tapes that typically feature water-activated adhesives. The backings are made from kraft paper, a high-strength paper material made from chemically-treated wood pulp. Kraft tapes require kraft tape dispensers, which apply a light layer of water onto the adhesive. Many kraft tapes are made with fiberglass stranding to boost their tensile strength. These tapes create seals that are robust and tamper-evident, providing additional peace of mind.

Filament Tape

Filament tapes are similar to many kraft tapes, as they are made with strands of fiberglass embedded in the material. However, these tapes are produced with plastic backings and rubber adhesives. Filament tapes are recommended for sealing packages containing heavy-duty and important items. These tapes are also great for light bundling applications.

Strapping Tape

Strapping tape is specifically made to bundle and palletize loads for shipping and storage. Typically made with acrylic adhesives, strapping tapes are durable tapes that are wrapped around pallets and boxes to hold them together as a single, solid unit, essentially performing the job of conventional stretch wrap. While stretch wrap may be a better option for long-term, high-volume usage, strapping tape is great for short-term, medium bundling and palletizing applications.

Machine Length Tape

Machine length tape is essentially carton sealing tape, but on an industrial scale. These rolls of tape are thousands of feet long and are specifically made to be used in conjunction with carton sealing machines. These high-capacity tapes are ideal for large operations with high-volume shipments that need to maximize their throughput.

Printed Tape

Printed tapes feature messages that either instruct workers on how to handle certain packages or warns workers about the condition of the package. These tapes are made with bright, contrasting colors and messages in bold, easily legible lettering. Caution tape and fragile tape are among the most popular types of printed tape.

Security Tape

Security tape is quite similar to printed tape, but with greater tamper-evident properties. On top of a warning message to check the condition of the packaging, these tapes are usually produced with a flashy pattern that is next-to-impossible to realign once broken. Security tape is ideal for sealing cartons containing expensive, valuable, and important items.

Class is Dismissed

And that’s a wrap on our Packing Tape 101! We hope you’ve gained both the knowledge and an appreciation for the different kinds of packing tape out there and what they can do for you. From carton sealing to strapping to printed, packing tapes comes in many varieties to serve a wide range of needs. Knowing your tapes means knowing what tapes to use for certain situations, thereby minimizing your costs and delays.

While you’re here, make sure you check out our wide selection of packing tapes, as well as other kinds of tape, like duct tape, masking tape, and double sided tape. All our tape products come with free shipping, so you can start your path to tape expertise today.

For further reading on packing tape and its importance in eCommerce, be sure to check out this article from Bloom Group S. A.