A lot of things can go wrong when you’re packing pallets, and the likelihood of failure increases with the more pallets you pack. However, there are numerous tips and tricks to keep in mind when packing your pallets that will ensure the security of your shipments and the safety of your employees. Here are the 6 best ways to pack a pallet for shipping:

Pick the Right Pallet

When you think of pallets, most people’s minds go to the classic, double-decker wood pallet design. But pallets are made of all sorts of materials. Quickly, the three main types of pallets are wood, metal, and plastic. Wood pallets are tough, easy to repair, can be recycled and reused, and are excellent for supporting heavy weights. Additionally, wood is typically the most cost-effective type of pallet. However, wood is a dense substance and the pallets’ weight can raise your shipping costs. Also, while durable, they’re prone to eventually fall apart, warp, and break, eventually losing the ability to provide support.

Plastic pallets are also strong but not as heavy as wooden pallets and are less subject to damage from wetness and corrosion. On the other hand, you can't just nail a new plank to a plastic pallet when it loses one, and they cost more per unit compared with wood. Metal pallets are extremely durable and less susceptible to corrosion and other forms of damage, but they’re much heavier and aren’t cheap. Pick the pallet that works best for the job while staying within your budget.

Know Your Pallets’ Limits

Now that you’ve selected a pallet, be aware of what it can and can’t do, and more importantly, what it should do. Check how much weight a pallet can hold. On average, a pallet of any sort can handle about 2500 to 2800 pounds of weight, but that can change as pallets are stacked. Still, keep that amount in mind, placing heavier and more durable items at the bottom and lighter, more delicate ones on top. Another average to remember is height. It is suggested that materials should not be stacked more than six feet high on a pallet, but again, investigate your pallet type’s limits.

Ensure Proper Packing

Add several layers and levels of protection between your products and potential damage from the outside. Use cardboard or plastic dividers and create a barrier for rough transit times. Take it a step further and add bubble wrap around fragile packages. To keep products from shifting, wrap a sufficient layer of stretch wrap around the pallet. As a final barrier, seal the edges with packing tape.

A Weighty Matter

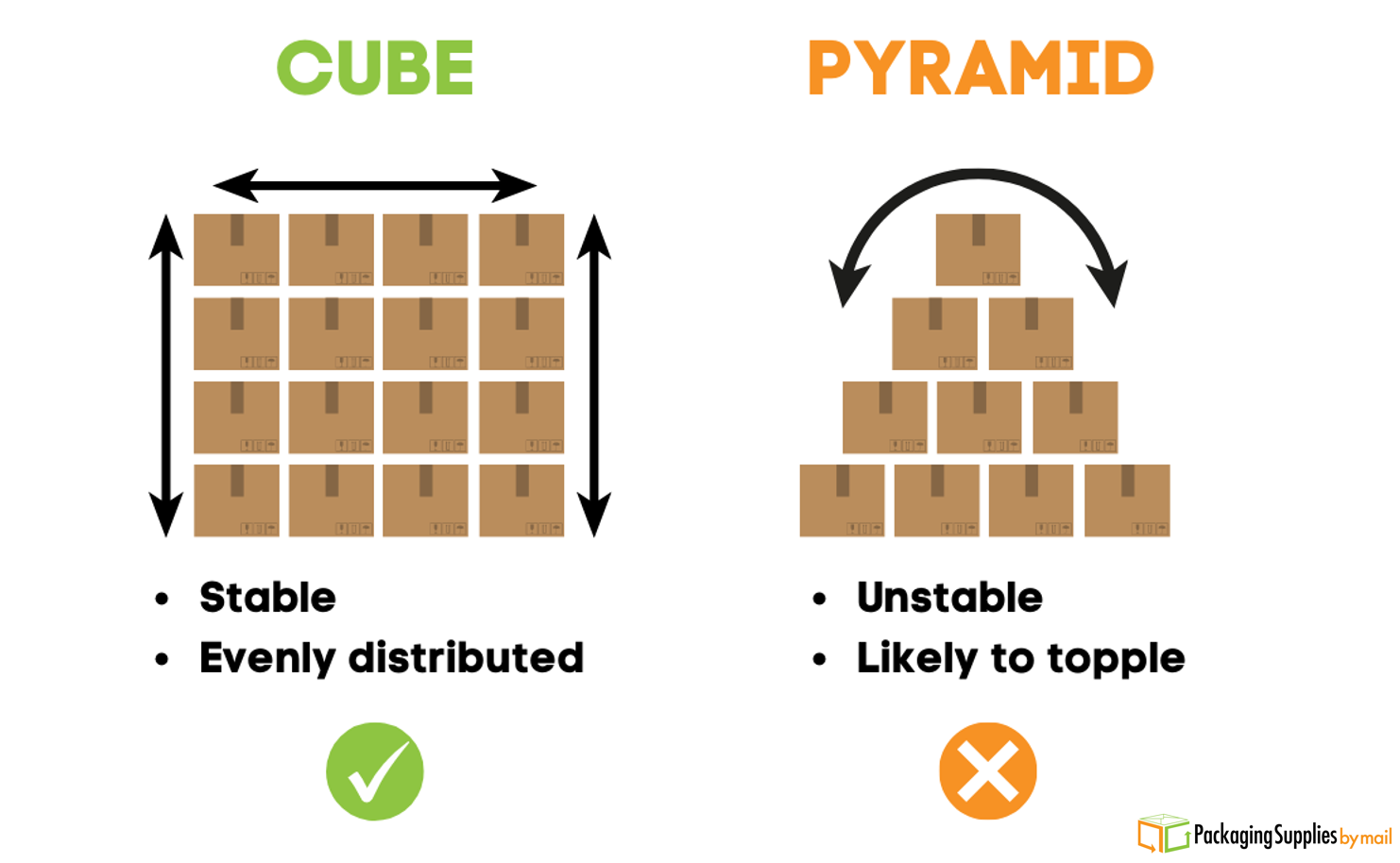

As mentioned, the best course of action is to build upwards, creating layers that run from heavier items to lighter ones. The collective weight of the items on the pallet will slowly compress all the boxes, so be sure the ones on the bottom can handle the pressure. Keep the weights nice and even as well, so one side doesn’t outweigh the other, leading to a potential collapse or “landslide.” One of the best pieces of advice from most experts is to stack packages the way you lay bricks: rotate them as you stack, so it’s less likely that they slip or become loose. Whatever you do, don’t stack boxes in columns; it increases the likelihood of them coming loose and toppling, if not during transit, then when they’re unloaded and unpacked at their final destination. Another piece of advice: think cube, not a pyramid. Despite appearing secure, the irregular shape of a pyramid is unstable when moving around a warehouse and the items at the top are likely to fall. A cube, on the other hand, is a much more stable shape and less likely to topple.

Even Steven

As mentioned above, top the stack off at a maximum of six feet and keep the distribution of materials even and squared off. If you notice anything sticking out, particularly toward the top, reconsider the current arrangement, dismantle the stack, and try again. Pallet contents must never lean or hang in any direction. Keep them straight, squaring off the corners and sides as you build upwards. As you stack, stick flat cardboard sheets between the stacks to help evenly distribute the weight and pressure. If you have heavy-duty corner boards, add them to the corners to provide greater protection and aid the bulk pallet wrap later in the packing process. And speaking of wrapping...

Wrapper’s Delight

Ready to wrap this all up? First, secure the pallet and cube with heavy-duty packing bands. Packing bands are made from several extremely tough and durable materials like rayon, polyester, polypropylene, and even steel. Strap down your packages with the bands, using two strips or more on each side, running the bands underneath the pallet’s bottom deck board.

Now that that’s done, get ready to roll with the bulk pallet wrap. If you have an automatic wrapping machine, follow the instructions and safety protocols of the device to set up and wrap your pallet and its contents. It should take no more than four layers to secure the pallet, although sometimes it can be less. When applying plastic stretch wrap by hand, tie the plastic to one of the bottom corners of the pallet and start wrapping from the bottom to the top. Cover each row with plastic twice and have about four layers around the entire package by the end.

FedEx has an excellent article delving into additional techniques for proper pallet packing, including labeling and other methods for securing a pallet.

These are the best ways to pack a pallet for shipping in 6 easy steps. Take time to remember them, but also realize that practice makes perfect!